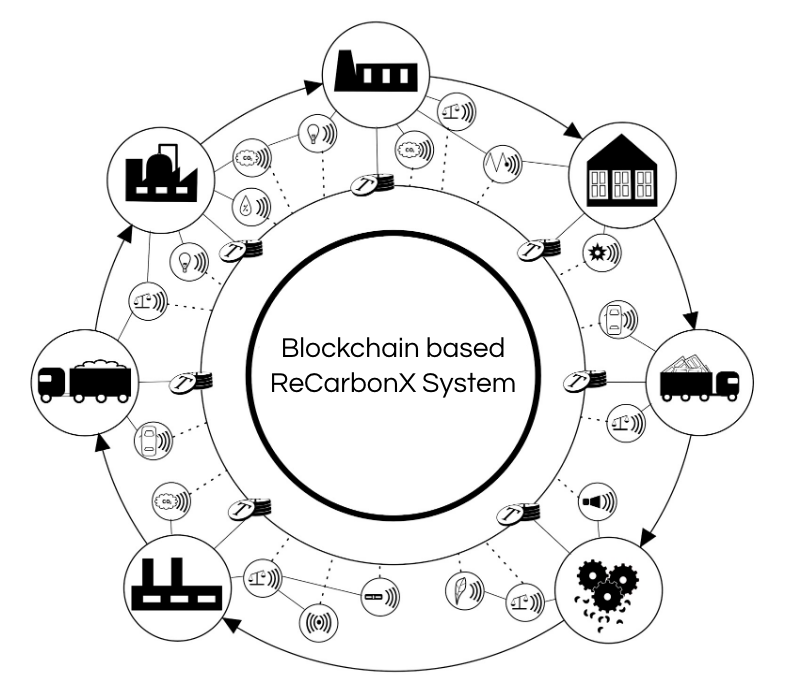

Smart Contracts and

integrated industrial sensors

built on a

blockchain-based system

The Blockchain Solution

Blockchain is a proven, secure technology that makes it possible to track and verify transactions and interactions at a scale previously unimaginable. It powers multi-billion dollar cryptocurrencies, and is more and more being integrated as a tool for transparency in traditionally complex and opaque systems. This is due to its unprecedented capability for global real-time tracking with minimum overhead, and its full transparency and reliability.

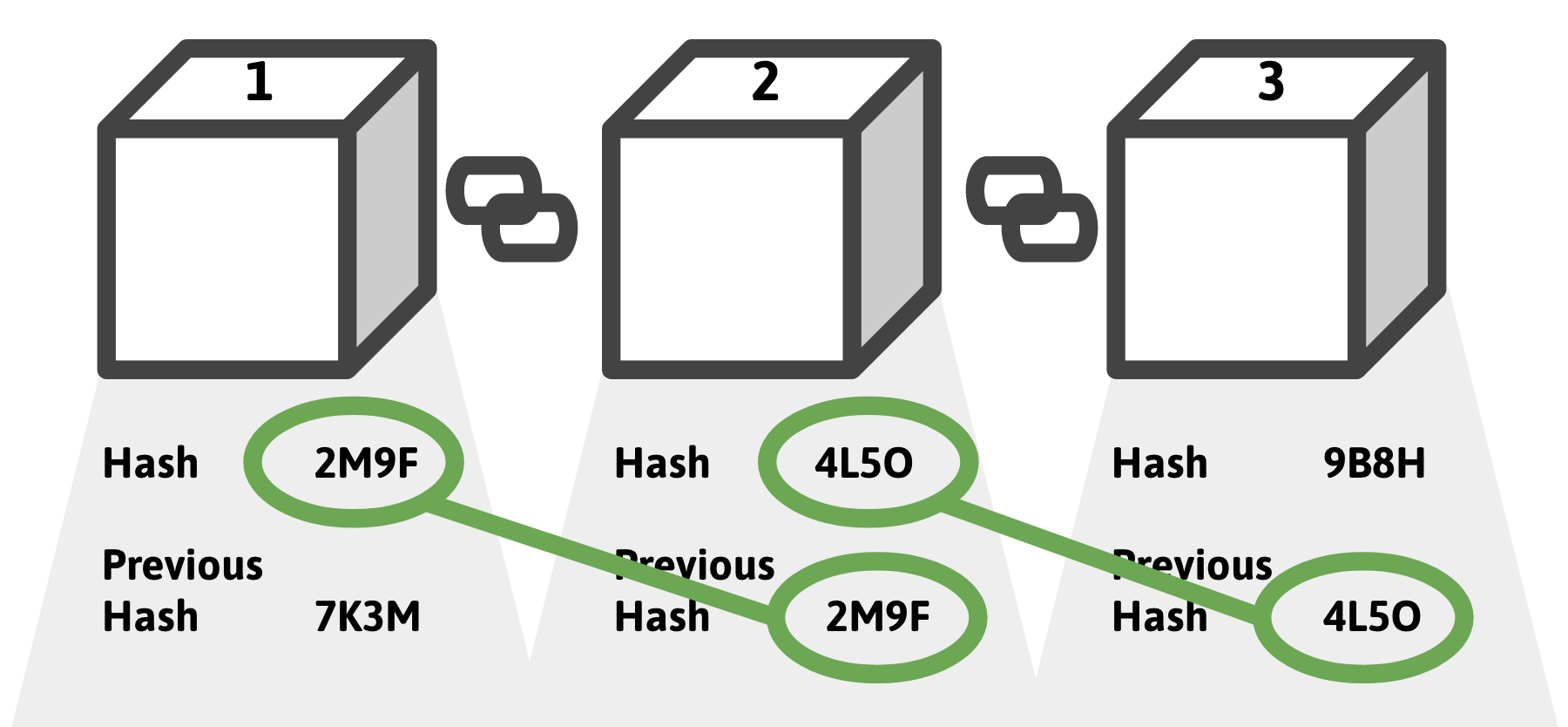

Data inside a block at each point on the chain is ascribed its own identifying ‘hash’ (or code). A hash is a mathematical ‘check-sum’, which is unique proof of data integrity.

If the data is altered in any way, that hash code is replaced with a visible-to-all, new hash that no longer matches the original data. If this happens, we know the data has been tampered with or altered in some way.

Secondly, every block in a chain also carries a second hash: the hash of the block that came before it in the flow of events. If there is a mismatch, we know the sequence of blocks in the chain has been interrupted.

Through each block’s verification of the previous block’s data, and by ensuring individual blocks in the chain cannot be altered, the entire chain is secured.

Because millions of identical copies of each chain’s distributed blockchain database are distributed across the internet, it is impossible to change any sequence without parallel access to millions of computers.

A blockchain therefore forms an unbroken, verifiable chain of custody for whatever good or service is being exchanged.

Blockchain systems operate on decentralized platforms (a specific chain for a specific series of events), and are thus free from at-scale security threats such as fraud and hacking.

Because blockchains are automated, they require no central supervision but, at the same time, they are transparent and auditable around the clock.

Due to decentralization, any blockchain also maintains independence from financial institutions and national governance, meaning data cannot be falsified according to third party pressure.

When combined with ReCarbonX’s Smart Contracts and Integrated Industrial Sensors, blockchain technology gives us the ability to track all points on a production chain: from type of energy source used, end-of-life materials collection, cleaning and re-processing to the origin of an animal’s feedstock, ingredients, environmental impact, new products manufacturing processes, supply chain, and sales in retail markets, to full product circularity.

Smart Contracts

Smart Contracts go hand in hand with blockchain technology, and have been reliably operating in the cryptocurrency world for some years. They are essentially a computer protocol that resides on the blockchain, which records and verifies all transactions and responds in a transparent and binary way to data changes and inputs.

Smart Contracts can thereby ensure automatic complex transactions and calculations, such as:

- verifying that an audited capacity matches the sum of products transferred;

- calculating the environmental impact of transportation based on distance and transportation mode; or

- that the energy demand for a production process matches the supplied renewable energy from an audited supplier.

When applied to real-world manufacturing supply chains this is good news, because these contracts eliminate the need for papers and forms. They also eliminate the need for a ‘middle person’—costly and time- (and carbon-) consuming in-person international exchanges become a thing of the past.

Smart contracts allow an auditor to view gathered data around the clock, and act as online, real-time validation—for instance, monitoring and verifying the plausibility of a transaction.

This means industrial certification such as Responsible Care and Sustainability Commitments may be granted in the knowledge that there has been no data tampering or falsification in between auditing periods, and that the integrity of product streams and reported emissions, etc., is in line with the physical reality of the process.

In the same way they ensure cryptocurrency transactions such as bitcoin are authentic, Smart Contracts can automatically ensure that recycled carbon content claims are based on real product manufacturing transactions.

Smart contracts can also calculate the CO2 emissions of a particular product based on its modes of transportation. This includes tracking fuel type and consumption, distance travelled, the transport mode (e.g. part by ship, part by truck) and the different fuel emissions from each leg of the journey.

In a similar fashion, they can determine product yields and energy demands of production processes, resource consumptions (like water use, waste production or ingredients), and all while removing the need for the producer to provide this information manually—and in a potentially erroneous way.

Smart contracts can be used to store documents such as certificates, audit reports, inspection reports, etc., in a transparent and reliable way, ensuring the originator and authenticity is proven and auditable by everyone.

Integrated industrial sensors

ReCarbonX integrated industrial sensors enable

real control of processes.

Once installed, the system automatically calculates and adds to a product’s overall footprint information.

We don’t depend on a client’s manual inputs and claims (e.g. “I have collected 789kg of plastic waste”); the system receives direct measurements (e.g. the exact weight measurement from an integrated scale).

A product’s CO2 emissions are calculated based on all the involved steps, including the distance and modes of transportation, types of fuel used, types of energy used for processing, temperature of conversion process, water usage and loss, and industrial waste treatment.

While smart contracts verify basic correlations between production variables, real process sensors can reliably and transparently measure and document relevant process data, such as online time and product quality parameters. We can showcase product quality data, the origins of raw materials, and modes of processing.

As a result, we can showcase the environmental impact of both visible (in our landfills and oceans) and invisible (gases) pollutants, both of which dramatically impact living conditions on the planet.